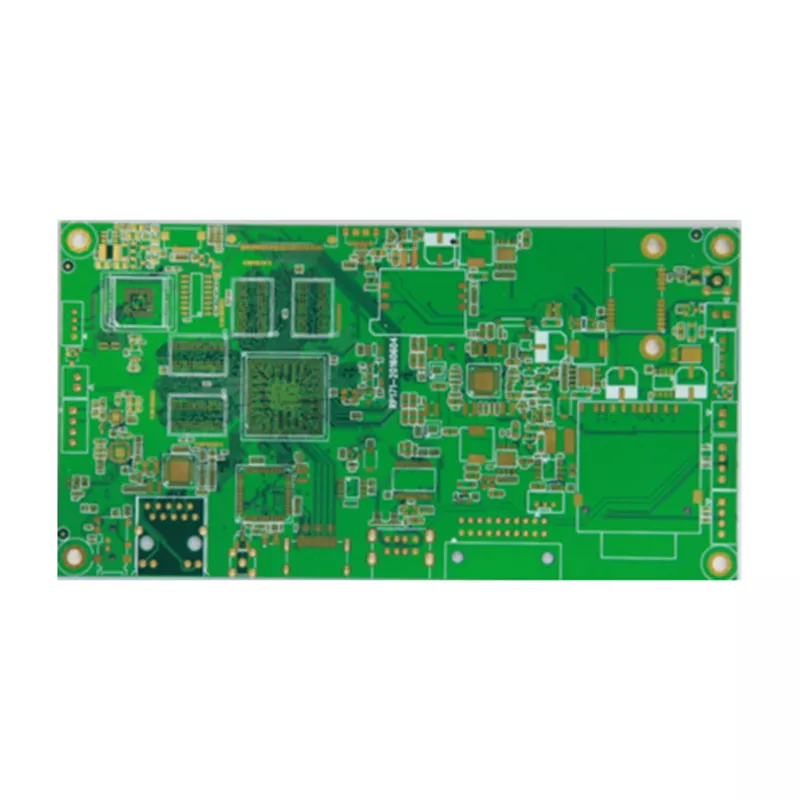

6-layer communication PCB

Shenzhen Huitong Kelian Electronics Co., Ltd., located in Shenzhen, Guangdong Province, China, is a professional manufacturer specializing in the manufacturing of printed circuit boards (PCBs). Our business scope covers Layout design, PCB manufacturing, PCBA assembly, component procurement, and testing services, committed to providing customers with one-stop solutions.

The company has a rich product line, ranging from double-sided boards to 36 layer high-end boards, covering various types such as ordinary FR4 boards, medium to high TQ value boards, thick copper boards, high-speed/high-frequency boards, ultra-thin/ultra thick boards, and environmentally friendly halogen-free boards. These products are widely used in various fields such as optical modules, industrial control equipment, communication equipment, consumer electronics, and military products.

We specialize in handling special processes such as half hole, impedance control, gold finger, disk hole, blind hole, and countersunk hole, and provide a variety of surface treatment options including ordinary lead spray tin, lead-free spray tin, nickel gold, electroplated nickel gold, electroplated thick gold, OSP, silver deposition, tin deposition, and composite processes. Our company has excellent process capabilities, which can accurately complete the placement and soldering of BGA, CSP, and LGA chips with small pitch (0.25mm pitch), while meeting the placement requirements of the smallest package 01005 components.

Our company has an elite team consisting of senior managers and a strong R&D team. Equipped with internationally advanced production equipment, such as fully automatic solder paste printing machines, 3D solder paste inspection systems, high-speed surface mount machines, large-scale welding equipment, AOI (automatic optical inspection) and X-RAY inspection equipment, as well as BGA repair workstations with optical positioning, ensuring excellent technical strength in special material applications, special process processing, and high-precision special board manufacturing.

Our company will implement strict testing procedures before production, including high-voltage testing, flying needle testing, and microscopic inspection. We rely on advanced testing equipment and experienced testing teams to ensure product quality.

For a long time, we have established stable cooperative relationships with numerous enterprises, and at the same time, we hope to have the opportunity to work with you to jointly promote the development of the industry.

Previous: No More